DIY: Oil pan installation! Reseal your pan, install a Killer B pick up or new headers! (04-08 Forester, 02-07 WRX, 04-07 STI)

For many Subaru owner’s the idea of replacing an oil pan rates right up there with a root canal. You know it needs to be done but you will put it off as long as possible. After a night at the drag strip with a few fellow Subaru owner who spoke about their STi engine failing after their brazed factory pick up split open and was unable to move oil around the engine. With this in my mind I went ahead and purchased a Killer B oil pickup, giving my engine more chances to fail from other issues.

The factory pickup in all its glory. The right side is where the known braze can split and cause a lack of oil pressure.

If you have an 04-0 FXT, 02-05 Wrx or 04-05 STi and are looking into Equal length headers you may need to change your oil pan to a 06+ STI pan to allow for proper clearance. I found this out the hardway when installing my MAPerfromance ELHs. You may also just have a leaky oil pan and want to take care of it.

06+ STI oil pan on the left and 04-05 STi pan on the right. The lower protrusion on the left side cause the MAPerformance header to be unable to be fitted.

New pan in! The headers fit just right!

Tools necessary for this if you have the engine outside of the car will be a 10mm, socket and torque wrench… Yep, that is all. If you are doing this on the car you will need to add a many 1/4’ extensions, and a 1/4th wobble, 12 and 14mm to your tool set. A set of pliers, a car jack, gasket remover tool and a paint scraper, rubber mallet can be helpful, if you want to get real trick you can add a pan separator in there to really speed up the process.

My favorite hand tools are linked here! I have had great luck with them over the last 6+ years of wrenching. The sockets are tough and I have yet to break one over my ownership.

Grey pneumatic 3/8 socket set Gear wrench 3/8 ratchet

One of my favorite photos of my tools. These are always by my side!

Power tools I use to speed up the job! Milwaukee is my go to company with a long warranty and great tools these might out last your Subaru! I have used them for the last 4 years and they make everything that much easier.

Speeding up your work and leaving your body feeling better after the install! These are always a great help when replacing parts!

Milwaukee 3/8 electric ratchet

Milwaukee 3/8 electric impact

Let’s get started with the removal of it while still on the car, as removal off the car is pretty straight forward.. With an odd start to replacing your oil you are going to remove your TMIC and undo the factory dog bone mount. Why do we start here you may ask…? We need to free up the engine/trans to be able to lift it later. You can also remove the 10mm bolt that holds the oil dipstick in place.

Uninstall the tmic and dogbone mount. We will need to move the trans and engine to move up.

After completing that lift your car off the group to give you adequate work space under the car. And placing your jacks in a safe area the holds the car stable but doesn’t interfere with the area you need to work in. I usually use the factory U-brace but there are many places to choose from. You can now began drain the oil.

If your engine is still in the car, we need to assume the position!

Up on jack stands and getting the oil out of the pan.

With the car in the air you can locate the motor mount nuts under the car. They are 14 mms and hiding behind the sway bar, now if you have an upgraded sway bar they may not be accessible and lowering the sway bar may come in to play. For my 24mm bar on the STI this is in fact an issue. Factory sized Forester bar will not be a problem.

Now we will take the jack and a plank of wood and place it on the transmission below the axles. From my reading you can also use the factory exhaust to do this, I have not tried it but it is an option. I prefer the trans option because it keeps it further from you working area.

Having these steps completed you can go a few different ways. You can remove the manifold/header now to give you more working room. I have completed this with the manifold on and with it off, removing makes life a lot easier. This gains you much more room for using tools to separate the oil pan from the block.

Exhaust manifold on, there is plenty of room to get these out.

Headers off! Plenty of room too!

04-05 STI and FXT oil pan on the right. Updated design on the left 06+ STi oil pan. Some headers have fitment issues with the old style pan and its larger design.

Removing the dip stick tube will be up next. I have had good luck leveraging it off with a pair of pliers but do not put some much grip on it that your crush the tube. There are two o-rings inside it and they can be quite troublesome to remove. Once removed it will stay trapped with the hoses and behind the timing cover.

Removing the factory dipstick tube.

We can now start with the main show! Wait we have all be waiting for… oil pan removal. All the bolts on the oil pan are 10mm and can be removed in any order. Most of these are quite easy to get to but four bolts. These four bolts reside on the backside of the oil pan and are the reason this is quite a pain. Without the wobble and extension set it might be time to ask you neighbor for a cup of wobbles and side of extensions.

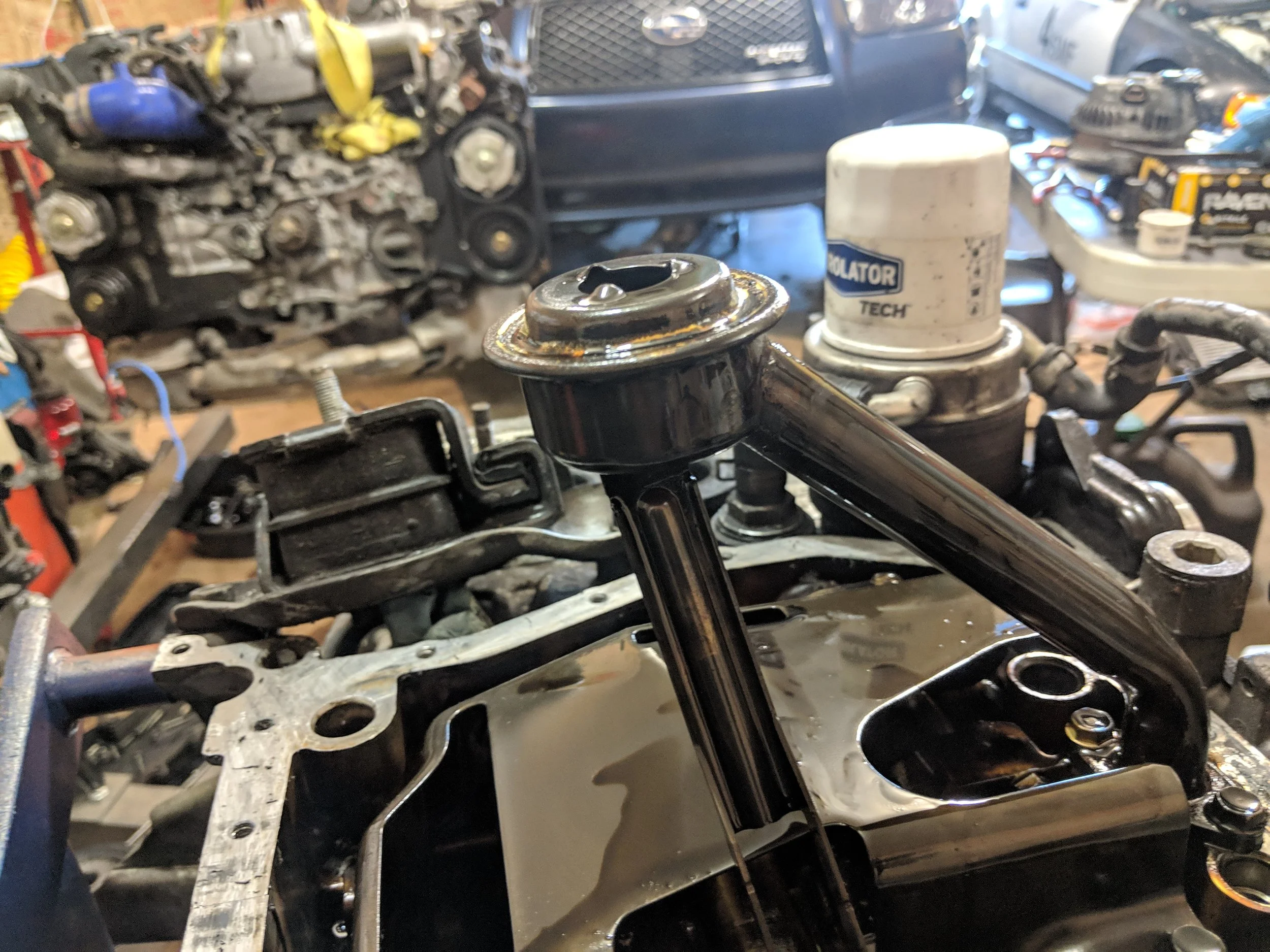

If you have the engine removed and you see any signs of leaking, just do it. This is so much easier out of the car. Also shown the four bolts that want to make your fun task a nightmare..

Another shot of the bolts. You can see how tight the backside bolts are with the engine upside down.

Well hidden this is the view from directly under the four hard to reach bolts. The bolts you can see are attached to the jacking plate below the transmission.

There is one of the four bolts, very well tucked behind everything.

My crazy tool setup for the oil pan removal when on the car. It works very well, the tape is there to keep it from moving too far. Works like a dream as there are two bends to move past.

Close up. The 10mm is attached to the universal joint, a 3” extension and a longer wobble extension.

With all the bolts removed your oil pan is probably still steadfast and holding on to the engine. Now the name of the game is breaking the gasket seal. This can be achieved with many different methods, for my oil pan I used a flat paint scraper to wedge in between the engine block and pan. Using this will not mar up any of the surfaces. Use the mallet to tap the paint scraper through the gasket material, twisting it back and forth when removing to help break away the gasket and release the hold. Another technique is to lightly strike the side of the oil pan to help break the gasket free. Taking care to not damage the pan if you are reusing it.

Pan finally off! If you look hard you can see the spot where the paint scraper entered right above and behind the dipstick tube hole.

Close up of the gasket material and the rubber gasket that can be replaced when the pan is off.

Much cleaning to do here and removal of the factory oil pickup.

Cleaned up quite well with the scraper and razor blade. Also a good shot of the two mounts the killer B unit uses over the one on the factory.

Other methods are screwdrivers and pry bars to pry the pan down, the downfall of these methods are bending the pan mating surface. Bending the pans mating surface is a surefire to cause a leak on start up or down the road after the repair. Be careful if you decide to try this method.

With the pan removed you can now add any upgrades you have to you oil pick up and pan baffle. I installed the Killer B oil pick up my STi and decided to put one in the new to me Forester motor. Some oil pick up tubes on ej25s have been known for cracking and causing a loss of oil pressure which can easily ruin a motor and your day. The torque spec for the oil pickup is 7.2 foot pounds.

Many of years of service ahead of this pickup.

If you have a new oil pan to install you can now prep the engine oil pan mating surface with a straight razor or your favorite gasket remover tool. Using a brake clean can help loosen the hold and help free the gasket up. You will also need to prep the oil pan surface too, once again use your favorite tool and technique. But be careful to not let the silicone gasket material to collect in the oil pan. If you do find some bits falling into the pan you can swish oil around in it and the drain the pan before installing it, this will help collect the gasket debris and flush them out. Otherwise, you can just hand pick up the pieces, you do not want these to make it into the oil pick up or oil galleys.

Cleaning off the gasket mating surface, while being careful to keep silicone out of the engine.

With your surfaces clean and smooth you can now apply your Fujibond, Grey Permatex or Hondabond. Remember that a small bead is more than enough, if you overdo it you once again can have silicone floating around in the engine. My Hondabond tip ended up gunked up from a prior project and I decided to use the old finger swipe technique. Basically leaving a thin layer of silicone on the surface, the oil pan has small indentations in between the bolt holes, I filled those with another thin layer to prevent any leaks from occurring.

Adding a bit of silicone to the low points on the oil pan. The engine block is all prepped up and ready to go.

After you have set all your silicone in place it is now time to seat the pan. Generally the silicone will hold long enough for you to quickly add a few bolts to keep it from falling down. You do not want to slide the pan back and forth when you pressing it to the engine. Falling oil can contaminate your seal and you can accidentally press the silicone out and into the oil pan. I like to place a few easy to each bolt s on all four sides of the pan and then quickly finish all the rear four pan bolts. This area seems the most prone to oil leaking and contaminating your pan seal.

Here are the four bolt holes that are a pain when doing this on the car. Quite easy when the engine is removed.

Having started all the bolts into the engine you can now run them in with your preferred method, i use the Milwaukee 3/8th ratchet with an adapter to to run all the bolts up but not excessively tight. Doing this in a criss cross pattern to allow the pan to seat properly and the silicone to evenly distribute. Now you can follow another criss cross pattern to torque all the bolts down to 3.6 ft pounds. Make sure not to overtorque these as they can easily strip/break and cause you so many more headaches than your current task.

When everything is all torqued up and you can now grab the oil dipstick tube and snap it back in. If your motor has a few miles on it this is a good time to install fresh seals. If you are having trouble installing the tube by hand, lube up the seals, line up the tube to the pan and give the top of the tube a strike with your rubber mallet. This should pop them right in and you can bolt it back to the engine.

With it’s two gaskets in it you will feel it pop into place twice. This shows that the lower gasket is in but the upper has yet to pop in.

Now you are able to fill your engine with its favorite oil. With it properly filled you can now start the car for the first time since replacement, start the engine for 5-15 seconds and then turn it off. Checking underneath the car for any leaks, if your floor is still dry feel free to start it up for a extended period of time. If your car is equipped with an oil pressure gauge this is a great time to use it. As with all my oil and coolant repairs I will lower the car down and back it out of the garage and double check for leaks. If everything still appears well I will take it for a short drive around the block and double check my work once more.

Finished up and checking for oil leaks. Peaking around shows it is all good.

Congratz! If the oil is still confined to your oil you have completed resealing your oil pan! If you installed a Killer B pick up you can now rest much easier knowing the brazed pick up is no longer there. If you replaced your pan for ELH enjoy the new rumble and horsepower!

Amazon links!

Dipstick tube o-ring (order two)

Craftsman universal joint set (wobbles)

Gasket scrapers (razor blade style)