Subaru headgaskets... Doomed to fail? What to look for when the temp gauge starts rising.

Subaru and headgaskets, it’s a match made in the depths of the Earth. If you weren’t aware it’s a habit Subaru has been trying to kick for many years, almost every EJ no matter sohc, dohc, Na or turbo has some issue with it’s headgasket. Being around Subarus for plenty of years I have seen quite a few issues and thought it was time to share helpful tips and knowledge to help you sort out this issue.

We will start out with the NA engines as these are usually the easiest to identify for headgasket problems. These tend to start leaking from the the external edges of the headgasket in between the cylinder head and engine block. In the Sohc Ej motors you can see this start to happen at or around 80k miles, sometimes sooner but mostly at this mileage and beyond. For those with turbo Ej’s a failing headgasket is usually an internal leak and typically found after 120k miles.

Typical lower headgasket seeping found on many older high mileage Ej engines.

Failed headgasket on cylinder number one of my Forester

Precaution

Anytime you are opening the coolant system always anticipate that coolant will come rushing out and cause burns. Wear proper safety gear and take the necessary steps to keep your self safe.

Diagnosis

First off is to pull the dipstick and just make sure there isn’t “extra oil” in there. A lot of V engines will have gasket failures that end up dumping coolant into the oil pan making a lovely chocolate milk drink inside the engine. In my witnessing of many blown Subaru head gaskets this is the least likely, unless you have blown the gasket in extreme fashion. Most Subaru head gaskets befall a slow and tedious fail thus not leading to catastrophic failures such as these. But it is always good to check before going further.

Pulling the dipstick is the first easy step, but as stated above I rarely see failures of this kind… Not saying it won’t happen just less likely. Coolant in the crankcase is a very easy way to ruin rod bearings too..

The next step in my process is a visual inspection of the coolant system, you certainly don’t want to chase after head gaskets when your issue is just a common coolant leak from a failed hose, radiator or clamp. If you own a coolant pressure tester this would be a great time to utilize it to find any small leaks. If you find that your coolant is well contained within the cooling system we will move to our next area.

Old and brittle coolant hoses can leak causing overheating issues. But if you find hoses that are swollen and pressurized after a drive with a rising temp gauge, head gaskets are a likely culprit.

Double checking that both hoses are clamped properly is a good first step.

The coolant overflow is a quick easy place to test. If your bottle is dark, murky and smells unlike coolant. An internal head gasket leak is very likely. You will often also see fluid pouring out as the radiator cap opens to relieve pressure as exhaust and overheated coolant make their way out

If your car is an automatic and you allow it to overheat often or badly, you can actually ruin the transmission as well. Most Subaru transmission coolers are located on the lower portion of the radiator.

Next up is the cooling fans are the operational? Are all the fan blades accounted for and are the fans plugged in? With the vehicle running you can enable the A/c and both fans should start running. We should also look at the front of the car and A/c condenser, if we can’t get airflow to/through the radiator it isn’t doing us any good, you can hopefully use water hose and just clean out any blockage to get the air flowing again. Another failure area can be a internally blocked radiator, this is quite hard tough to test given the A/c condenser’s location, with the coolant flowing through the system you will want to check for uneven temps across the radiator, showing a lack of flow throughout the tiny passages of the radiator. Without running fans you could easily cause a headgasket failure.

Checking your fan blades for damage or obstructions is just another step to your detective work. Also make sure the wiring is connected and not damaged.

After these checks there are only a few places left to check. First up is having the proper radiator cap(s) that are in working order. First wait till your car has sat off for hours and the cap is cool, otherwise hot coolant can/will erupt when removed. You can now check for any physical damage of the seal or spring. Given their price you can probably just replace these but if you’d like to test them you will need a radiator cap tester to make sure it can hold pressure for over five minutes. A collapsed radiator hose is also a sign of a failed cap.

Proper radiator cap (also the upper reservoir tank for turbos) pressure value is necessary for cooling. I recommend using the factory Subaru cap for your application. Subaru turbo radiator cap

A bad coolant temperature sensor can show incorrect values on the coolant temperature gauge. You will likely see an engine code for a failing sensor as the correlation between many other sensor values will lead the ecm to find this data as faulty. You will likely experience poor starting and mpgs with an incorrectly reading sensor.

If you are looking for coolant temperature, look know further. It is located behind the alternator. Not a likely area of failure for most Subarus but it is worth a check if you have any weird circuit codes

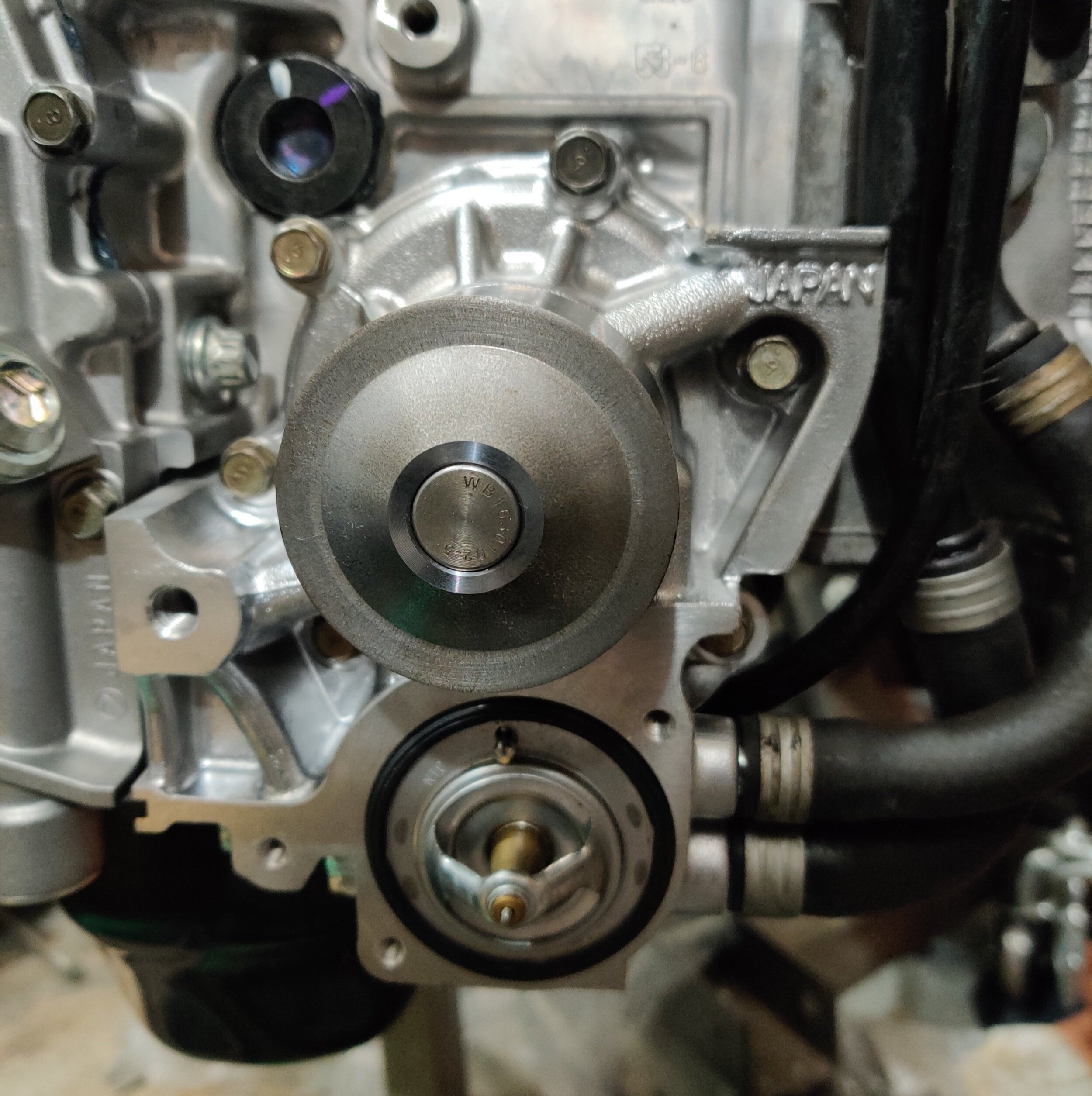

Our last couple of areas are the thermostat and water pump. If either fail to operate you will lose coolant flow thus causing an increase in coolant temperature within the whole the system. The thermostat’s job is to hold the coolant inside the engine until it overcomes a specified temperature (generally in the 180-200 F range) when this value is reached the coolant is released from the engine and through the radiator to keep it cool. The water pump is just as the name implies, it is the workhorse of the system allowing the coolant to pushed and pulled throughout the system to keep the temperatures consistent. It’s very seldom to see a failed water pump on a Subaru but it is a possibility.

Another area worth a check is the thermostat and water pump assembly. The water pump bearing can fail causing coolant to come out of the weep hole.

The weep hole can be viewed on the right side of the water pump. It’s the dark hole in between the gasket mounting holes. Aisin WPF-023

What’s next?

After checking all the above parts you haven’t found a specific overheating cause to your issue… Where do you go looking next? The next few steps are my personal methods based on what tools I have on hand, they are all searching for exhaust gases within the cooling system which is your likely culprit if all the above parts are working.

The first and likely easiest/quickest method is using a coolant filling bucket while allowing the engine to run. With the engine cold you will attach the bucket to the radiator and fill the bucket halfway full. Then starting the engine you can allow it to get to operating temperature watching for bubbles within the funnel. Now you can idle the engine up in park/parking brake engaged and watch a constant stream of air/bubbles and or an increase in fluid height. Bubbles are a sign of an internal head gasket leaking exhaust gases into the cooling system.

If you aren’t purging air from the system and are seeing large pockets of air coming to the top and rising coolant level you likely are facing head gasket failure. Coolant funnel spill free

The most specialized test will be a Combustion leak tester which comes equipped with a special fluid that changes colors after coming in contact with exhaust gases. You will fill the test chamber to a level line and hold it above an open radiator cap while using the bulb to draw in any exhaust gases. The presence of combustion gases will change the blue liquid to yellow. The only downside to this product is that sucking in coolant can change the color, but that is why you fill it to the specified line. Also it’s usefulness can be in question if you are only buying it to test one car.

This magic fluid changes color when combustion gases come in contact with the fluid. Block tester kit

Another method for testing is to use a coolant system pressure tester on the radiator cap opening(System needs to be cold before starting) and then starting the car. Watching for a pressure increase on the gauge. I feel this method isn’t always foolproof because a very small leak may not have enough pressure to make an impact on gauge. But you can regularly borrow these from the parts store making it a cheap test if you don’t want to purchase any tools.

A multicap cooling system pressure tester. This allows you to pressurize the system to find any leaks. If you are worried about a head gasket failure and have this tool on hand you can connect it and watch the gauge for an increase in cooling system pressure while the car idles. Radiator and coolant system pressure tester kit

Hopefully these tips and tricks have solved where your trouble stems from and you can now take care of business.

If you have read this and found it above your pay grade, you might want to find a reputable Subaru shop to do the testing for. Better than throwing parts at it and wasting time and money.

Amazon links

Radiator and coolant system pressure tester kit

Coolant funnel spill free

Aisin WPF-023

Subaru turbo radiator cap